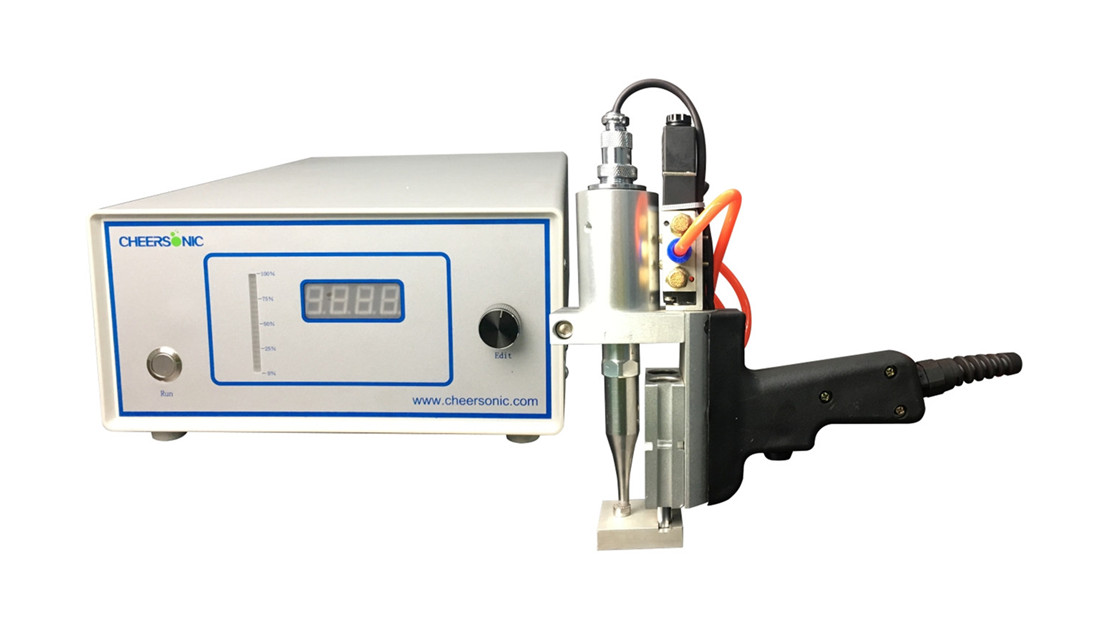

Ultrasonic Handheld Welding Machine

Ultrasonic handheld welding machine uses a transducer system to convert high-frequency electronic energy into high-frequency mechanical vibration, which is transmitted to the weldment through the welding mold, so that the joint surface of the material is rubbed sharply at high frequency until it melts, resulting in a molecular link between the joint surfaces of the weldment. It solidifies into one body, and the gluing process is completed in an instant. Ultrasonic spot welding machine has the advantages of high power, strong penetrating power, standing operation, etc., including time control, mainly used for welding, riveting, etc. of plastic products, such as welding of waterproof panels.

• Wide range of applications, with spot drilling and spot welding functions;

• The operation is flexible and simple, and it can be used after the 220V power supply is connected;

• The whole machine is exquisitely designed, easy to carry, and small in size and does not take up space;

• High-quality imported ultrasonic transducer with strong power and good stability;

• The noise is low and the working environment is environmentally friendly;

• Set working hours according to customer needs;

• Easy to control the use of a small diameter gun.