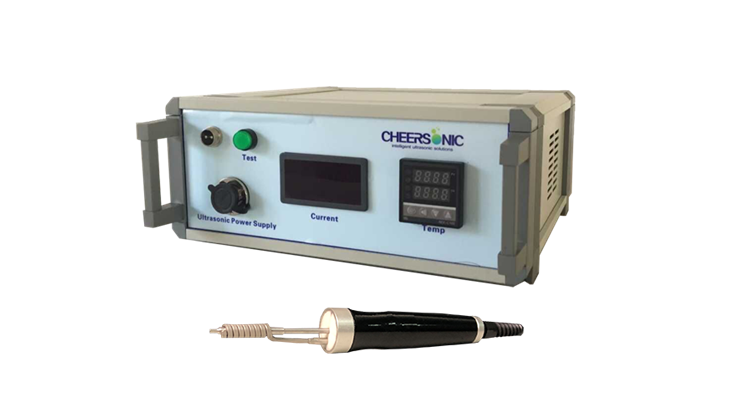

Ultrasonic Electric Soldering Iron

Ultrasonic Electric Soldering Iron – Sonic Welding Machines – Cheersonic

Ultrasonic soldering machine (ultrasonic electric soldering iron) is a new type of ultrasonic welding tool, which firmly combines the solder with the surface of the welding object through ultrasonic vibration. It is widely used in precision welding of glass, ceramics, silicon crystal devices (LED, liquid crystal, etc.), and superconducting materials. , Electronic product packaging and other metal and non-metal welding.

Application scope and industry

Ultrasonic soldering irons can be used in special industries, such as the welding of solar cell bus bars, high-precision soldering of superconducting materials, ceramic parts and other places where traditional soldering irons cannot be operated.

• Thin film solar industry

• Electronic products, improve sealing and lead solderability

• Laser sensors, heat exchanger diodes, etc.

• LED, diodes, kinescopes, fluorescent lamps, monitors, motors, transformers, CCFL, refrigerators, air conditioners, etc.

• High-precision welding of superconductor materials

• Mass-produced instruments and equipment admission test, scientific experiment, etc.

Advantage outlook

• No need for flux, effectively prevent bubbles and pinholes, reduce defect rate and reduce welding time, improve welding quality, and prevent false welding.

• The solder joints in the welding zone are smooth and beautiful, and there are no bubbles or false soldering inside the solder joints to prevent oxidation.

• Perfect welding of the object to be welded, high solder joint strength, not easy to aging, no internal and external pressure stress, high success rate of one-time welding

• Perfect integration of welding and motherboard can be performed to improve system stability.

• There will be no air bubbles inside the weld, no oxidation, anti-corrosion plastic handle

• High temperature resistant stainless steel pipe, lead-free welding head

• The tin material is of good quality and low price, which can reduce the cost of consumables