Ultrasonic Cutting Polypropylene Bag

Polypropylene bags are bags made from the synthetic plastic polymer polypropylene, a frequently used material in consumer goods and some industrial applications. It is used for bags because it is strong, flexible, and can be made transparent. Polypropylene bags are manufactured for a variety of uses. Polypropylene is used for bags less commonly than polyethylene, another plastic polymer and the most frequently used material for disposable plastic bags and packaging, but is superior to polyethylene for bags that are meant to be reused. Polypropylene bags are strong puncture resistant bags used for transporting a wide variety of materials. Polypropylene is currently one of the fastest growing polymers. Much of this growth is attributed to polypropylene’s ability to displace conventional materials (wood, glass, metal) and other thermoplastics at lower cost. Polypropylene (PP) is a tough, rigid plastic.

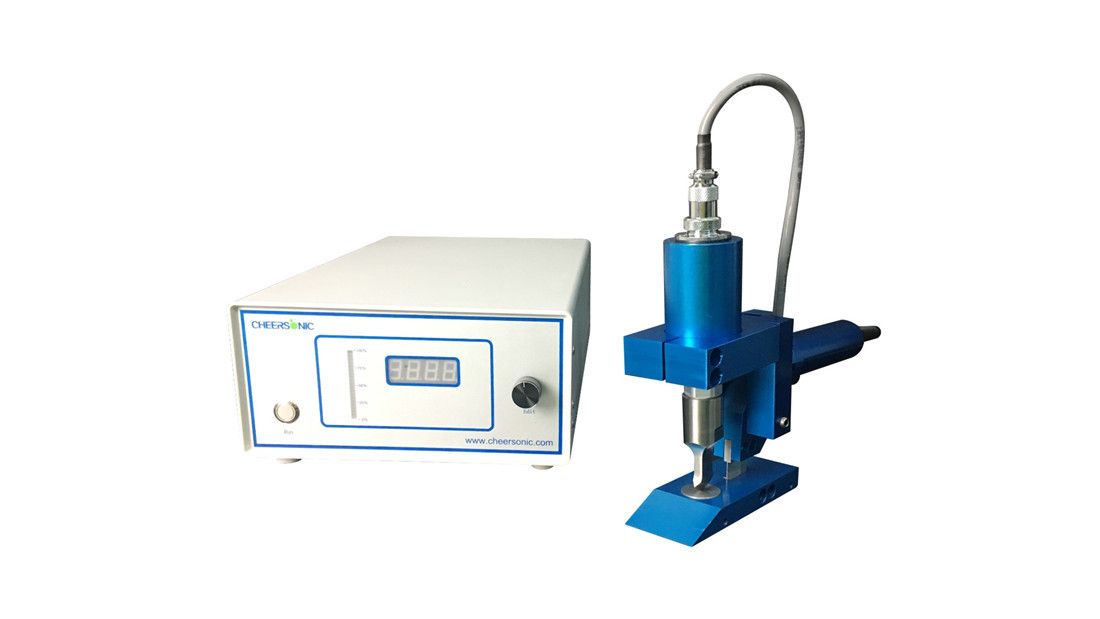

Ultrasonic cutting technology offers various advantages, especially in sun protection, final make-up, ribbons, technical textile, filtration fabric or packaging industries. This technology performs clean and soft edges, without fraying, overthickness, burning or yellowing, but also strong and regular welding without any additional material such as glue, staples, rivet, etc. Many sorts of acrylics and synthetic materials such as kevlar, acrylics, PVC, polyester, non-woven, screen and synthetic fabrics-cotton blends would be cut and weld by the ultrasonic cutting technology. Ultrasonic cutting machine could be operated manually and perform precise linear cuts on polypropylene bag. Our industrial range has been developed to perform any kind of continuous operations of edge cutting or centre slitting. Our devices are compact and adapted for integration on looms, stenters, inspection machines or off-line machines. It allows to perform sealed edges, without fraying and very resistant.

Cheersonic is an expert manufacturer of ultrasonic equipment. We have focused on ultrasonic sewing technology more than 20 years. The ultrasonic technology and automated system are researched and developed all by ourselves. In our sample and testing studio we are offering the testing of your material. According to the needs and testing result, Cheersonic would customize ultrasonic solutions for you.