Ultrasonic Apron Welding

“Apron” comes from the Medieval French word ‘naperon’, meaning small tablecloth. Since this word was often mispronounced as ‘an apron’, in the 17th Century, the garment eventually became known as an ‘apron’. Over the years, aprons have been worn as part of uniforms, trades and rituals or simply as fashion statements. The best materials or fabrics to use in aprons are often 100% cotton (canvas or denim) or poly blends (poly/cotton or poly/viscose). Cotton based aprons are super durable, designed to fade and soften with repeated washes, whereas poly/blends are lightweight, super durable and colourfast.

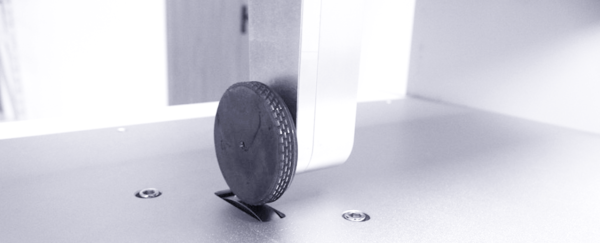

Ultrasonic apron welding offers some key advantages over other forms of welding: It saves time. It is much faster than traditional welding methods, as virtually no time is needed for drying or curing. It is a highly automated process, which also saves on manpower and helps you get the parts you need faste. Ultrasonic welding has some advantages ,such as high precision, low cost , high speed and it produces very little noise, performed without any lubrication and doesn’t use chemicals in its process.These machines are highly versatile so they can be easily modified for different applications such as cutting glass, plastic, ceramics, etc.

Cheersonic has focused on the technologies of ultrasonics and automations for more than 20 years, and supply a series of standard ultrasonic sewing machine as well as bespoke ultrasonic sewing solutions for different industries, such as automotive, hygiene and medical, filtration, industrial safety and so on. Our factory is strictly in terms of ISO9001 manufacturing the high quality & reliable ultrasonic machines.