Project Description

Ultrasonic Wetsuit Seamless Sewing

Wetsuit is a diving supplies. It is used to prevent loss of body temperature when diving too fast and cause heat loss, while it also protects the diver from reefs or pests plants. The most common wetsuit fabrics are nylon and lycra.

Diving clothes fabric has very good waterproof performance. The interface of fabric sewing water seepage phenomenon can not occur, because the body and the external water needs to be completely isolated. The traditional sewing technology is to use needlework fabric connection, can not meet the waterproof performance requirements diving suit, so the fabric for diving suit need to choose a special sewing method.

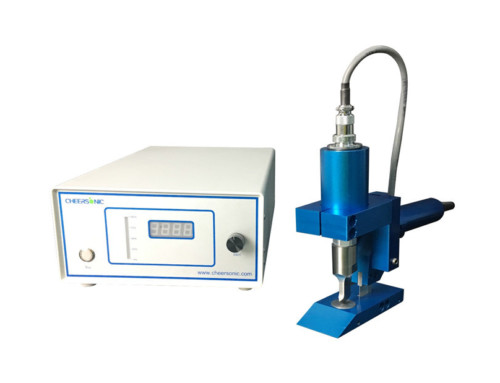

CHEERSONIC Ultrasonic developed ultrasonic seamless sewing equipment to achieve complete sealing. The working principle of ultrasonic seamless sewing is that the high frequency oscillation is used to transmit the ultrasonic wave from the welding head to the welding surface of the work piece. The friction of the fabric cloth of the diving suit cloth reaches the melting point of the fabric, and then dissolves rapidly to form a welding (sewing).

Seamless sewing technology Compared with the traditional needle sewing technology, ultrasonic seamless sewing technology more robust, able to withstand more than 5 times the external force. And ultrasonic seamless technology to reduce the industrial and labor costs.

Written by Alisa Yu