Project Description

Ultrasonic Nylon Button Welding

Nylon button is commonly used as a clothing attachment materials, both sides of the molecular mother. It is a fine, soft fiber and on the other side is the harder hooked bristles. In addition to clothing, widely used in various fields, life can be seen everywhere.

With the changes of the times and the progress of science and technology, the traditional nylon button production technology has been unable to meet the requirements of people for its beauty and long-term use performance. Traditional nylon button mainly rely on the production of two ways: one is the needle sewing, needlework sewing cloth with no binding between, but by a thin line to tie them together after long-term use of the connecting wire is easy to break, resulting in nylon button failure, and the sewing interface is clearly visible, poor aesthetics; the second is the adhesive connection, this way nylon button aesthetics than sewing needle high, but there will be degumming after long-term use, Lead to nylon button failure.

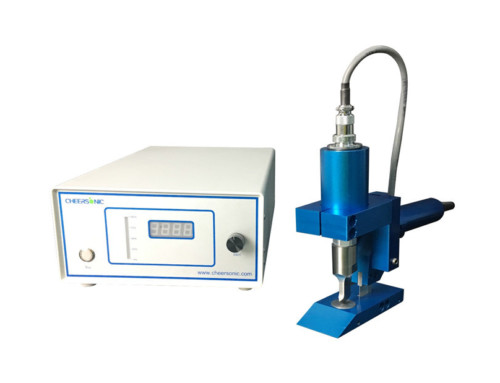

CHEERSONIC understanding of the customer’s needs, we recommend using CHEERSONIC ultrasonic independent research and development of ultrasonic welding equipment.

Needless sewing equipment, no glue, without any auxiliary material can be V elastic ribbon or ribbon welding together. Ultrasonic welding equipment is the mechanical vibration of ultrasonic energy can be focused on the ultrasonic horn, the ultrasonic horn through the ultrasonic energy transmitted to the weld zone, as the two welding at the interface acoustic resistance, it will have a local high temperature, resulting in two fabrics The contact surface melts quickly, plus a certain pressure, make it integrated into one. When the ultrasonic stop function, let the pressure continued for a few seconds, so that its solidification molding, thus forming a solid molecular chain, to achieve the purpose of welding V, welding strength close to nylon button raw material strength.

Written by Alisa Yu