Project Description

Ultrasonic Horns / Fixtures

Ultrasonic horns (i.e., tooling and fixtures) is a critical element in the welding assembly process. Ultrasonic horns and fixtures must be designed to accommodate the requirements of a particular application.

To obtain a quote, please contact us at market2@cheersonic.cn.

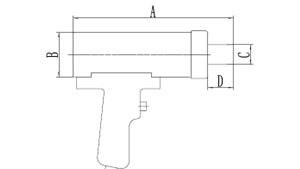

Ultrasonic Horns

Ultrasonic horns design and manufacture

Applying the welder of a documented work process, Cheersonic’s highly skilled ultrasonic tooling engineers design and manufacture durable, dependable horns and fixtures that can be used with Cheersonic welder assembly equipment, as well as competitive equipment.

Ultrasonic Tooling – Horns / Fixtures

Evaluation

An ultrasonic tooling engineer considers factors related to materials, engineering, and labor in the early design stage. Application specifics such as size, shape, material, function, etc., are all evaluated.

An ultrasonic tooling engineer considers factors related to materials, engineering.

Design and documentation

Cheersonic uses computer-aided design technology to design ultrasonic tooling. Each step of the design, manufacturing, and testing phases is meticulously documented. Structural and material data are stored for easy retrieval, review, and modification, if necessary.

Ultrasonic Tooling – Horns / Fixtures

| Model | Horn |

| Dim.(mm) | 15-200 |

| Cable Length(m) | 3 |

| Weight(kg) | 0.8 |