Project Description

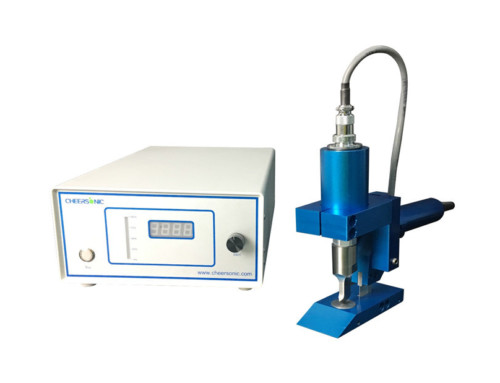

Ultrasonic Filter Seal

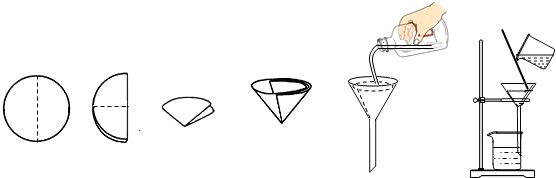

Filtration is the removal of liquid (or gas) through the media, solid particles and other substances in the suspension (or with solid particles of hot gas) under the action of propulsion or other external forces, so that the solids and other substances are separated from the liquid Or gas) separation operation.

Where the fabric is a commonly used filter medium. Filter cloth in the industrial varieties of the most widely used.

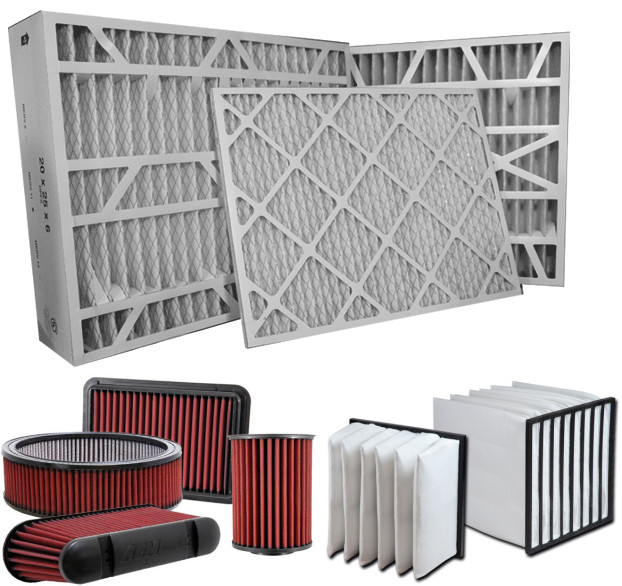

Filter cloth is divided into textile filter cloth and non-woven fabric. Its composition materials are natural fibers (cotton, wool, silk, linen) or synthetic fiber. Filter cloth filter performance depends on the material, fiber weaving and post-processing. The most common are foldable filters, bag filters, panel filters and so on.

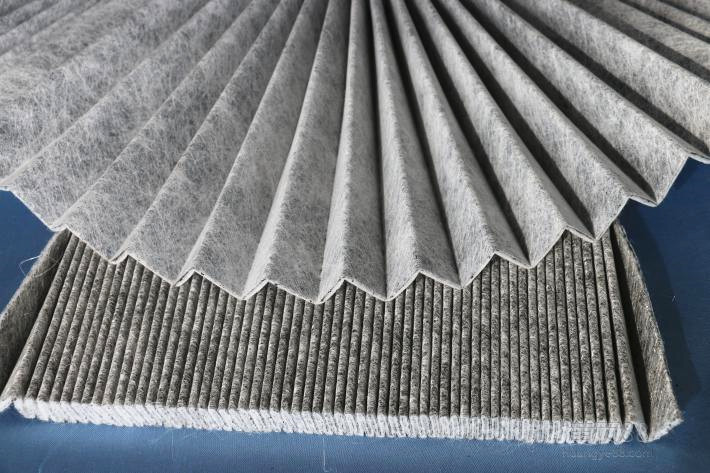

The use of traditional sewing technology can not be done for customers to require seamless sewing requirements.

Nowadays, the filter cloth is the use of ultrasonic technology for sewing seal.

Ultrasonic sewing equipment is the use of ultrasonic principles directly to the fabric fusion connection, no suture.

CHEERSONIC research and development of ultrasonic sewing equipment, is a new type of processing technology, seamless fit. It eliminates the traditional sewing process, in the fabric is divided into a number of squares when the use of advanced ultrasonic sewing process, so that the fabric is no car suture, to achieve true seamless sewing. As a customizable system that requires the use of ultrasonic welding technology to handle a large number of filter cloths, it is possible to continuously seal various filter-type filters and to have a longer weld length, no rupture, no burrs, no curl, and a high degree of beauty.