Project Description

Container bag ultrasonic wireless sewing

Container bags, also known as tons of bags, space bags, etc., it is a unit of container equipment, which together with the crane or forklift can be achieved unitized transport package. FIBC is suitable for shipping a large number of bulk and granular materials. It is widely used in the transportation and packaging of powder, granule and lumpy products such as foodstuffs, grains, medicines, chemicals and minerals.

There is a great demand for container bags in various industries. The quality of the container is the key factor, of which the safety factor is particularly important. The safety factor is the ratio between the maximum capacity of the product and the rated design load, mainly depending on whether the content and the bag body are abnormal or not and whether the connection is damaged when the content of the container bag is multiplied several times. Similar standards at home and abroad, the safety factor setting is generally 5-6 times.

The main factor affecting the safety factor lies in the handling of the container bag sewing. In the past, bulk bags mainly rely on solid sewing connections. When the container is under heavy load, the suture is greatly stressed. Once it exceeds the limit that the suture can bear, the container sack will break instantly.

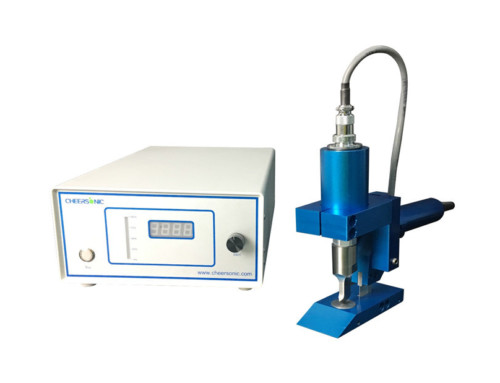

CHEERSONIC ultrasonic bagging sewing research. We take the three kinds of common container bags as the research object, under certain conditions of time, temperature and pressure conditions by ultrasonic wireless sewing equipment welding, and the same fabric sewing interface fracture rupture strength, water pressure and water degumming comparison. The results show that the strength of the three kinds of fabric joints are beyond the strength of conventional forms of stitches. Therefore, ultrasonic wireless sewing equipment processing can not only be waterproof and breathable, giving the joint good flexibility, and can be a good bag of seams on the strong requirements, the safety factor can reach more than 6 times.

Ultrasonic wireless sewing equipment works: the use of high-frequency oscillation by the welding head to the sound wave transmitted to the workpiece welding surface, the moment molecules of the work to produce friction to achieve plastic melting point, thus completing the rapid dissolution of solid materials to complete the welding. Its junction strength is close to a single piece of continuous material, as long as the mating surface of the product is designed to match, you can achieve a complete seal.

Written by Alisa Yu