Airbag Welding

Airbag Welding – Ultrasonic Seam Machine – Cheersonic

Airbags are typically made from woven fabric, which may be coated or uncoated but must be impermeable to gases and flame resistant. Nylon textiles such as Nylon (polyamide) 6.6 are among the most common fabrics used to weave airbag cushions for general manufacturing and automotive applications.

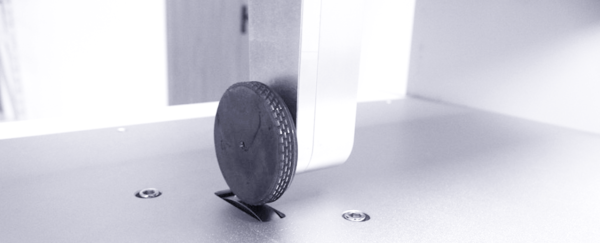

Ultrasonic airbag welding means the cohesive bonding of thermoplastic fabrics through internal friction, heating and fusion of the material. The ultrasonic sewing technology is a modern, innovative and economic alternative and complementary to conventional sewing technology. Workpiece is held between the sonotrode and the anvil wheel and welded continuously under pressure. Ultrasonic energy provides savings, efficiency and clean production opportunities in the area where it is used. The ultrasonic sewing technology is widely used in producing Dust Collection Bags. Flat-layed goods, three-dimensional structures, hard-to-reach small parts, closing or closed mouldings – an optimal free arm is available for every application.

Cheersonic is an expert manufacturer of ultrasonic equipment. We have focused on ultrasonic sewing technology more than 20 years. The ultrasonic technology and automated system are researched and developed all by ourselves. In our sample and testing studio we are offering the testing of your material. According to the needs and testing result, Cheersonic would customize ultrasonic solutions for you.