Ultrasonic Awning Welding

Ultrasonic Awning Welding – Ultrasonic Sewing – Cheersonic

An awning or overhang is a secondary covering attached to the exterior wall of a building. It is typically composed of canvas woven of acrylic, cotton or polyester yarn, or vinyl laminated to polyester fabric that is stretched tightly over a light structure of aluminium, iron or steel, possibly wood or transparent material (used to cover solar thermal panels in the summer, but that must allow as much light as possible in the winter). The configuration of this structure is something of a truss, space frame or planar frame. Awnings are also often constructed of aluminium understucture with aluminium sheeting.

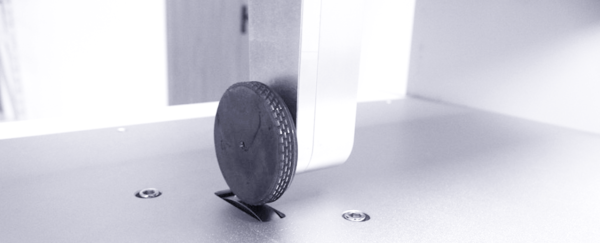

Ultrasonic awning welding offers some key advantages over other forms of welding: It saves time. It is much faster than traditional welding methods, as virtually no time is needed for drying or curing. It is a highly automated process, which also saves on manpower and helps you get the parts you need faste. Ultrasonic awning welding has some advantages ,such as high precision, low cost , high speed and it produces very little noise, performed without any lubrication and doesn’t use chemicals in its process.These machines are highly versatile so they can be easily modified for different applications such as cutting glass, plastic, ceramics, etc.

Cheersonic is an expert manufacturer of ultrasonic equipment. We have focused on ultrasonic sewing technology more than 20 years. The ultrasonic technology and automated system are researched and developed all by ourselves. In our sample and testing studio we are offering the testing of your material. According to the needs and testing result, Cheersonic would customize ultrasonic solutions for you